Hi Jonas! Can you tell us a bit about yourself and your role?

I'm a Global Sustainability Specialist in Siemens Gamesa, so I'm the focal point for sustainability-related matters, especially towards our customers. I try to analyse our customers’ demands and translate them into actions, whether in procurement, technology, operations, and so on. It's a broad role with sustainability in the centre.

I have a background as an environmental engineer, and I have a PhD on sustainability in the wind business. When I was studying there were still discussions about whether climate change was real or not; the last eight years have really transformed the debate. That's true in the corporate world as well. We used to think about green products, now we think about sustainability as a core part of strategy.

What’s the biggest challenge you face, and how are you addressing it?

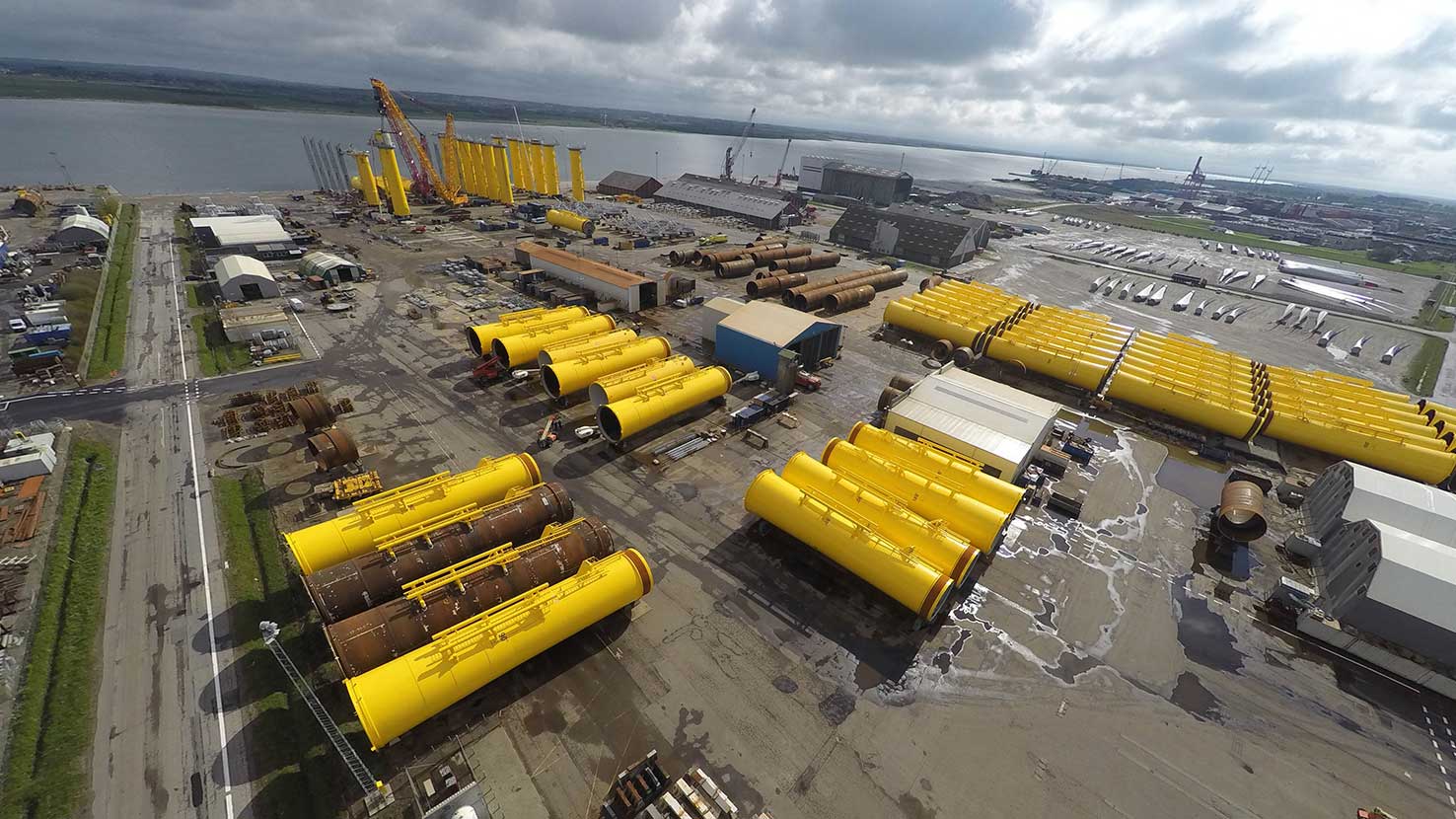

Siemens Gamesa produces wind turbines, and when it comes to decarbonisation, our biggest challenge is the manufacturing of the wind turbines themselves. Steel makes up most of the tower and is used in other components, too; fully decarbonised steel would halve the carbon footprint of a wind turbine.

When you’re facing a big challenge, you need a target, and in 2021, we moved our net-zero emissions target forward by a decade, with an aim to reach net-zero by 2040 instead 2050. One reason for this was our engagement with Ørsted: It’s very important for us to meet the expectations of our customers, not just in terms of the product, but in terms of sustainability across our value chain. We also believe that by being ahead of the curve we can help motivate others and catalyse change, giving our global society a chance to reach the goals of the Paris agreement.

Of course, targets are nothing without actions. Our aim is to develop steel based on hydrogen and green electricity, thereby eliminating carbon emissions. We see early signs that this can be done, but it needs to be proven on a commercial scale.