We're passionate about the communities where our wind farms are located. Find out how we work with them.

The basics of electromagnetism and its use in onshore wind

We can create electrical energy by rotating magnets inside a coil of conductive wire. We just need something to make the magnets rotate.

Fossil-fuel power stations burn coal, gas, or oil to heat water, producing high pressure steam that drives a turbine and, in turn, an electrical generator.

But this also produces carbon dioxide and other harmful emissions, and relies on finite resources that need to be continually extracted from the ground and transported to the power station.

In a wind turbine, the magnets are instead rotated by the clean, natural, and unlimited power of the wind.

The components of an onshore wind turbine

To capture the wind’s energy, the top of the turbine faces the wind and the blades are set at exactly the right angle. The air moving past the blades then makes them rotate.

In the nacelle – the non-rotating part at the top of the turbine – the blades’ rotation passes through a drive shaft, often via a gear box, to rotate magnets inside a coil of wire. This produces an alternating current of electricity.

Why do we have onshore wind farms?

One wind turbine can produce a few megawatts of energy. That’s much less than the steam turbine in a fossil-fuel power station, which is why wind turbines are grouped together to create a wind farm.

The wind farm is like one big power station – but one that doesn’t produce any emissions when it generates power.

An onshore wind farm consists of many turbines spanning a wide area. Each one is fixed to a foundation, with a tower rising into the air where the blades meet higher wind speeds.

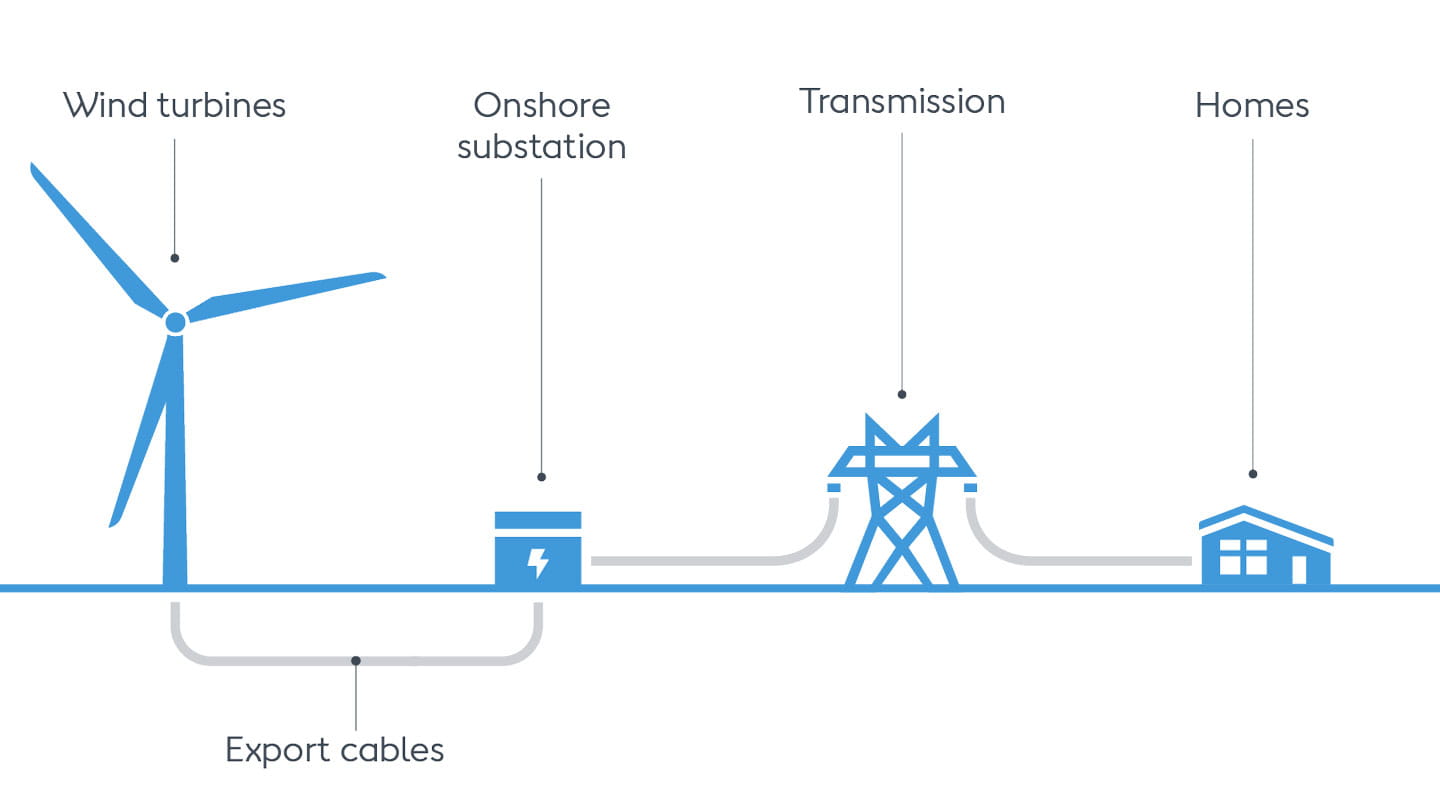

Transporting onshore wind energy

The power from each wind turbine travels through cables to an onshore substation. Here the voltage is adjusted so the electricity can be fed into the grid and distributed via power lines to homes and businesses.

The teams that keep the blades turning for 25 years

We expect a wind farm to be in commercial operation for at least 25 years.

During this time, it is serviced and maintained by a team of wind turbine technicians. The technicians use their knowhow, along with the latest technological innovations, to keep everything working, troubleshoot any technical problems, and carry out inspections.

Did you know?

Onshore wind not only creates jobs for turbine technicians, but also generates work, opportunities, and economic benefits in the communities where it is located.

When a wind farm reaches the end of its life

When a wind farm reaches the end of its life, we either decommission it, extend its life, or repower it.

- Extending a wind farm’s life means:

Repairing and maintaining the turbines for further years of service

- Repowering a wind farm means:

Replacing the old turbines with the latest larger and more efficient models

- Decommissioning a wind farm means:

Completely dismantling the wind farm

When repowering or decommissioning, we need to remove the old turbines. Up to 95% of a wind turbine can be recycled, but the lightweight blades present more of a challenge.

In 2021, we committed to send no more blades to landfill, but instead to explore ways to reuse and recycle them.