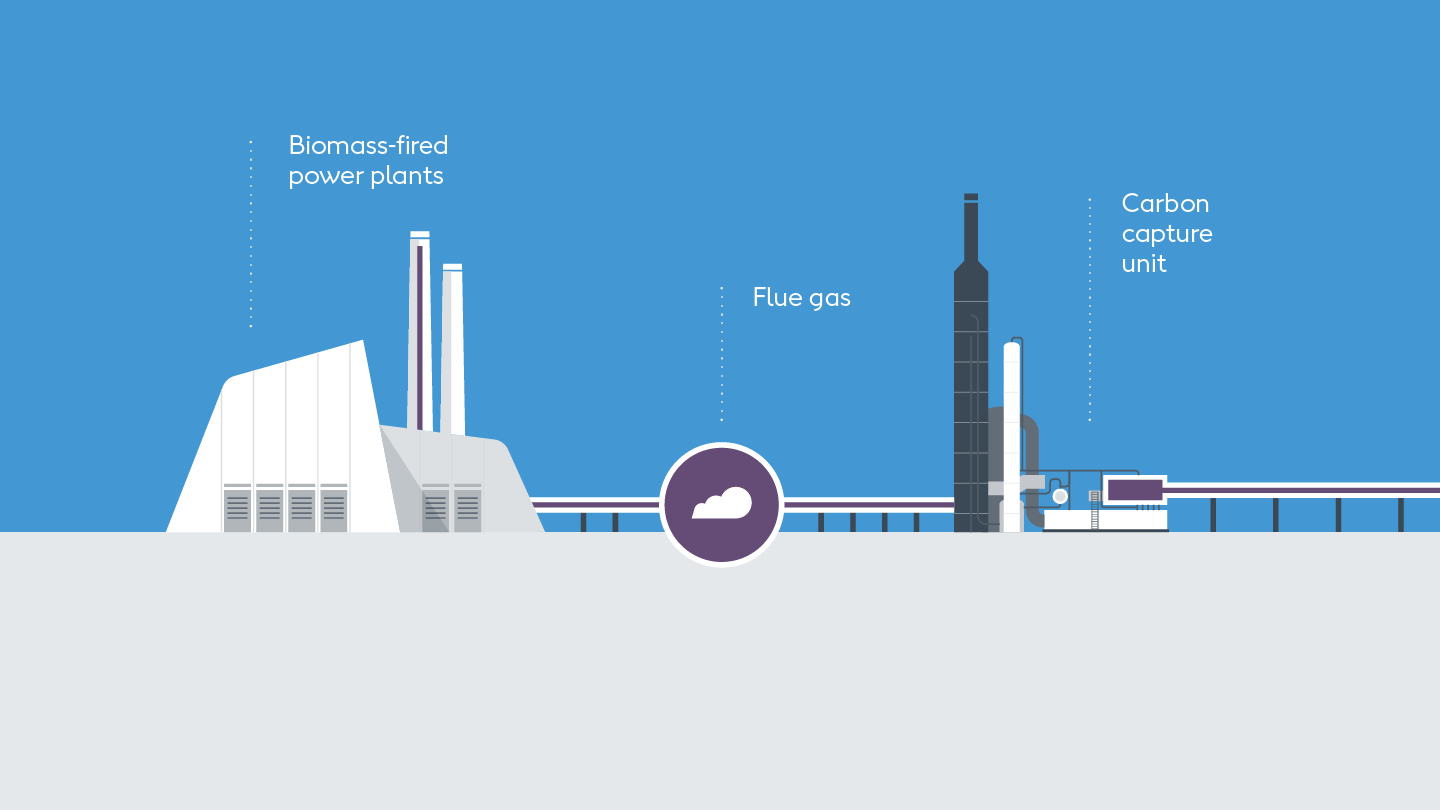

Find out about the technology that allows us to capture biogenic CO2 at two of our biomass-fired heat and power plants.

From end 2025, we’ll capture CO2 at our woodchip-fired Asnæs Power Station in Kalundborg and at our straw-fired unit at Avedøre Power Station in Greater Copenhagen

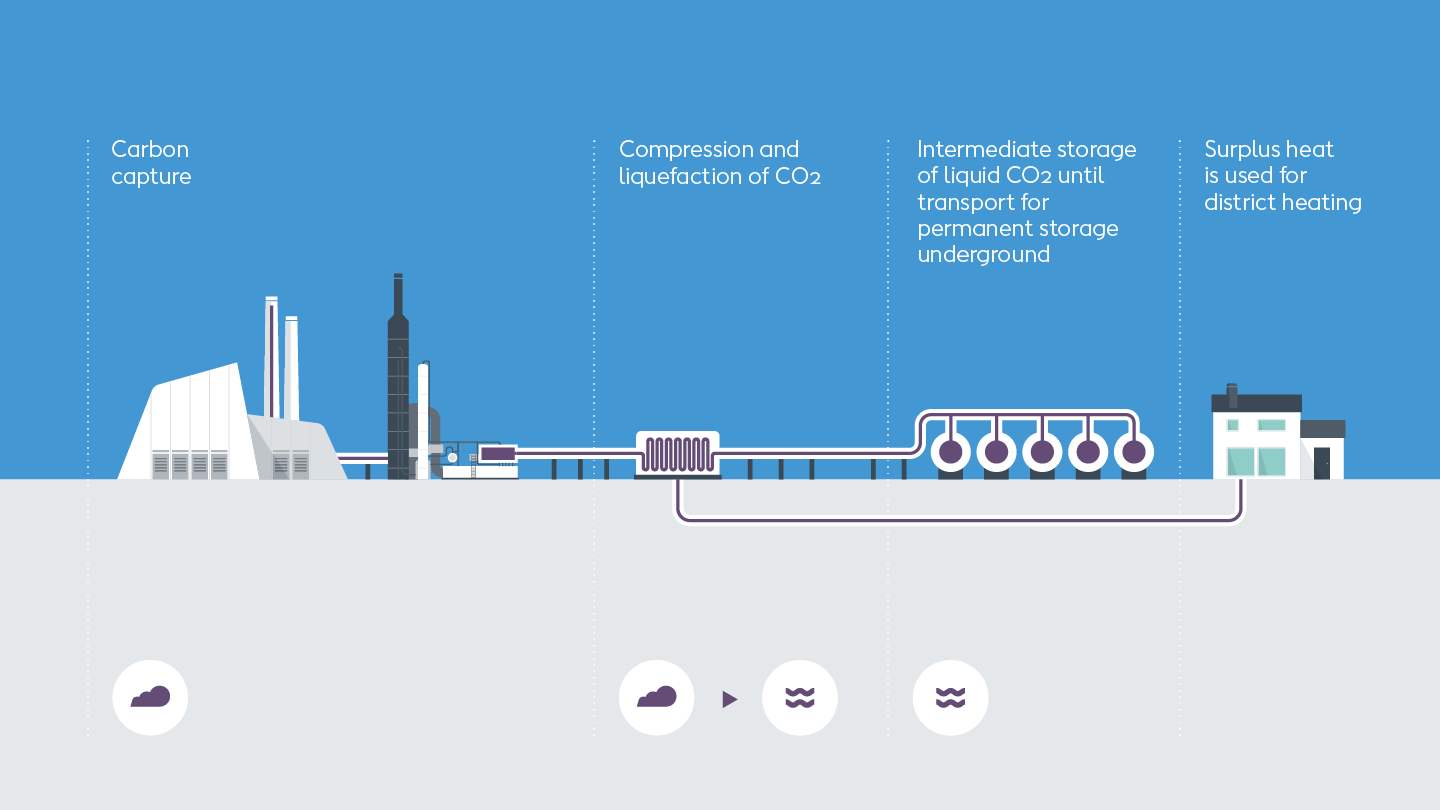

Step 1 – Capturing the CO2

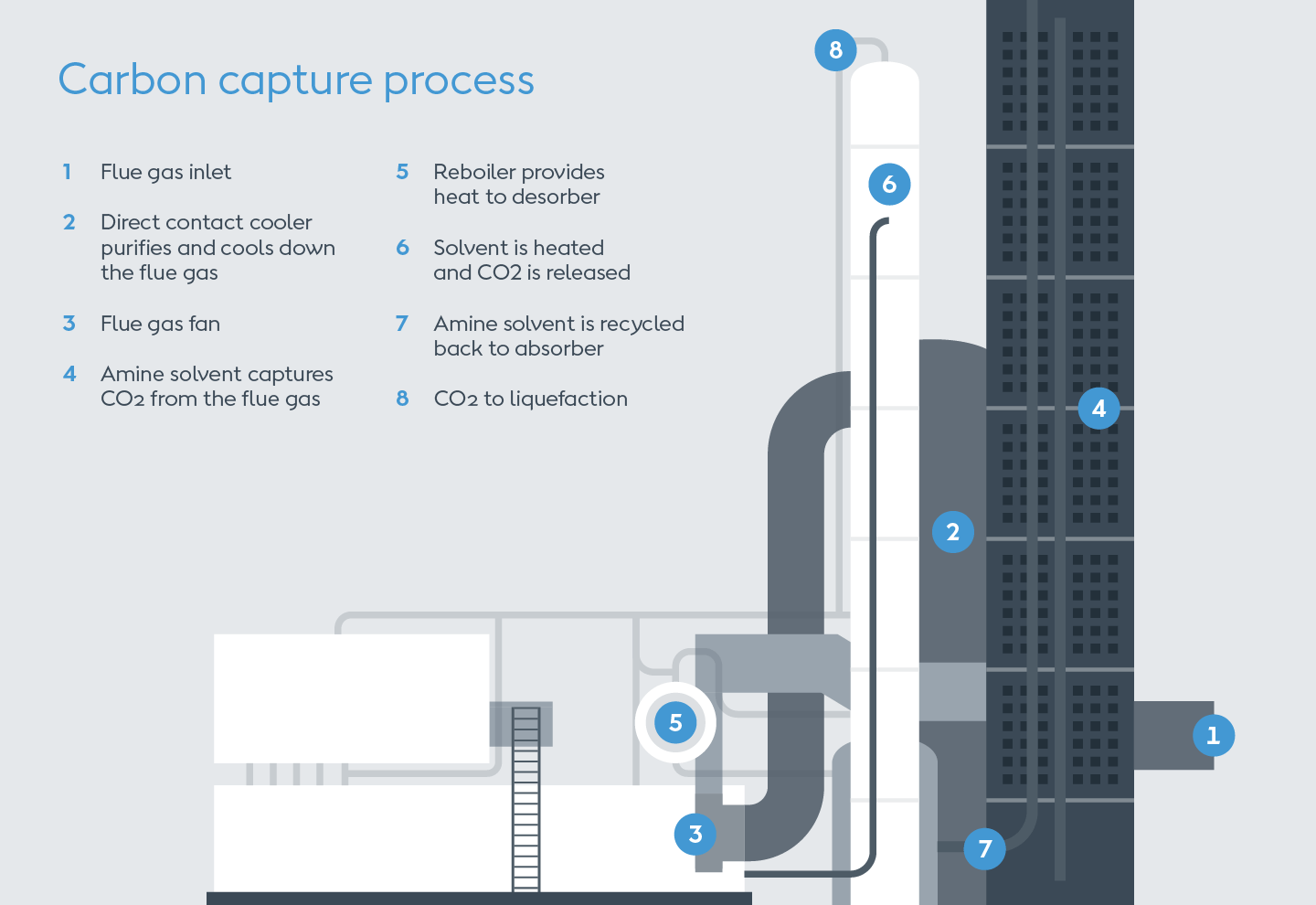

The first stage of carbon capture and storage (CCS) is to capture CO2 from flue gas that comes from power plants.

The CO2 capture units we use are from SLB Capturi. They have a total capacity of 65 tonnes of CO2 per hour, and the carbon is captured through amine washing. CO2 is separated from the flue gas stream through a scrubbing process in which 90% of the CO2 content in the incoming flue gas is captured.

When the CO2 gas has been captured by the capture units, it’s transferred to compressor and liquefaction units.

-

Learn more about CO2 capture technology

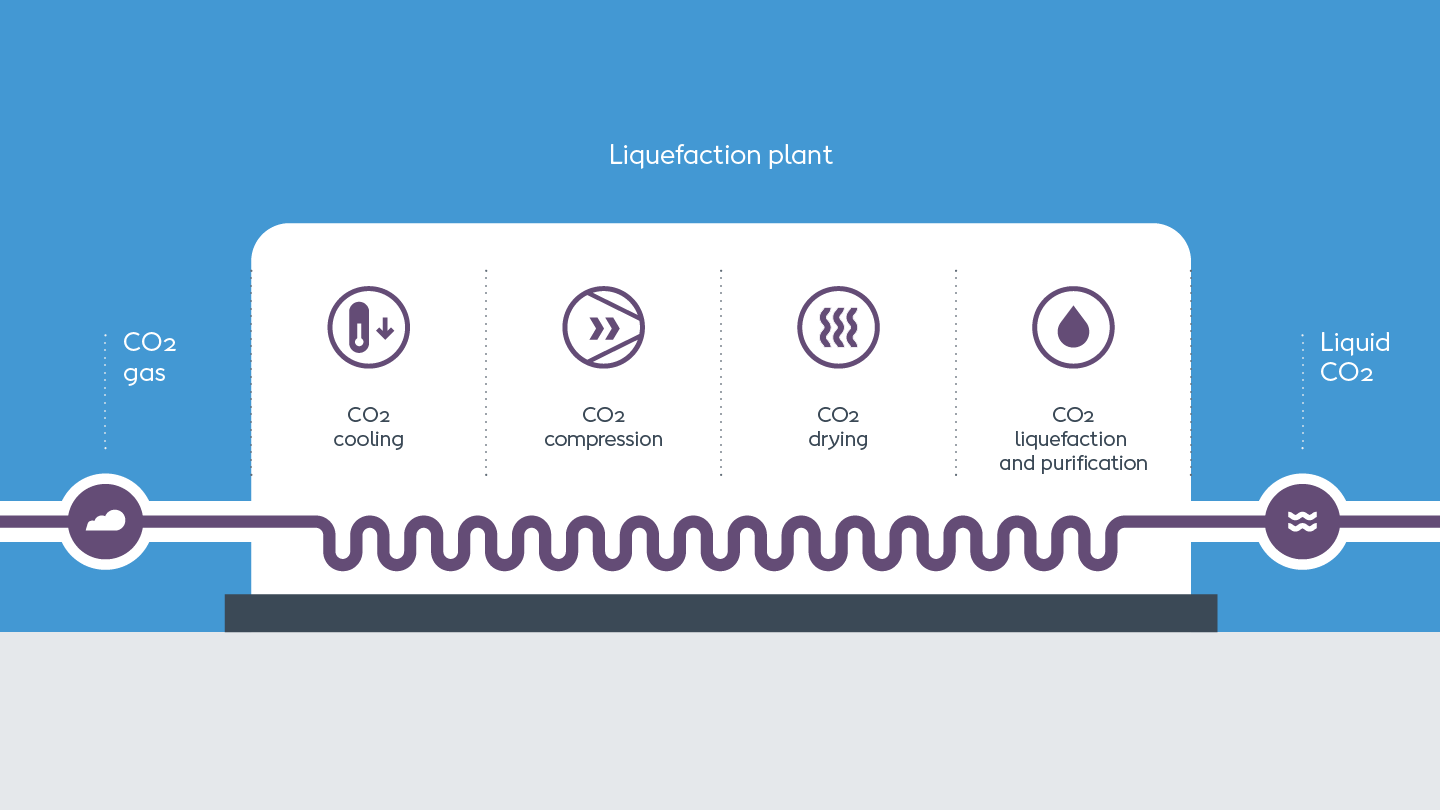

Step 2 – CO2 compression and liquefaction

The liquefaction units compress and cool the carbon stream, which turns the gaseous CO2 into liquid form. This is done by a compressor with intercooling, where the generated heat is utilised for district heating or cooled, depending on the district heating demand.

The liquid CO2 is sent for intermediate storage in insulated pressurised tanks.

Step 3 – Intermediate CO2 storage

The third stage after CO2 capture, compression and liquefaction is intermediate storage of the liquid CO2 in pressurised tanks. Liquid CO2 is stored at 15 bar(g) and -26 °C.

The intermediate storage ensures that carbon remains in liquid form until the product is exported. The tanks are cylindrical steel tanks that are up to 30 m in length and 6.5 m in diameter.