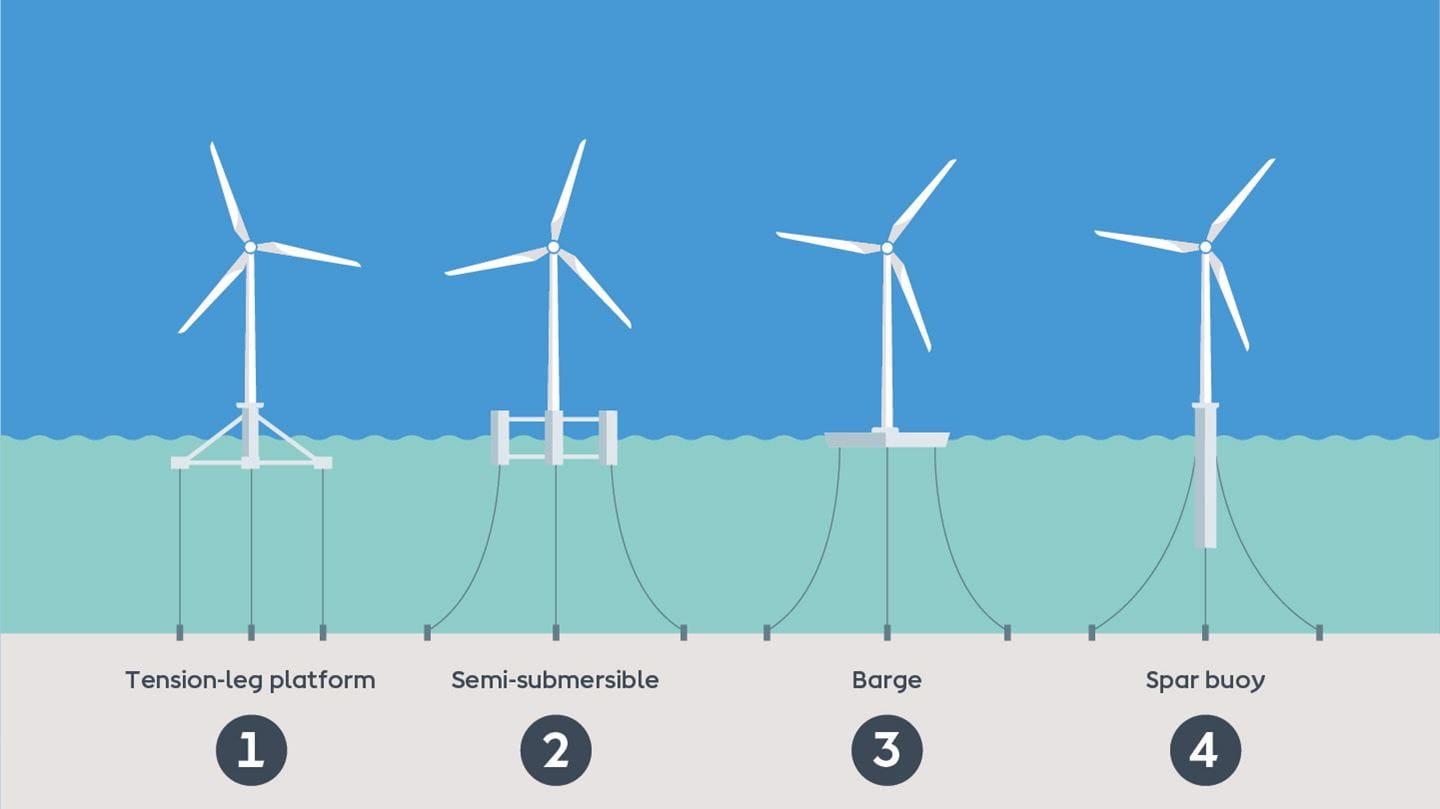

| How it works |

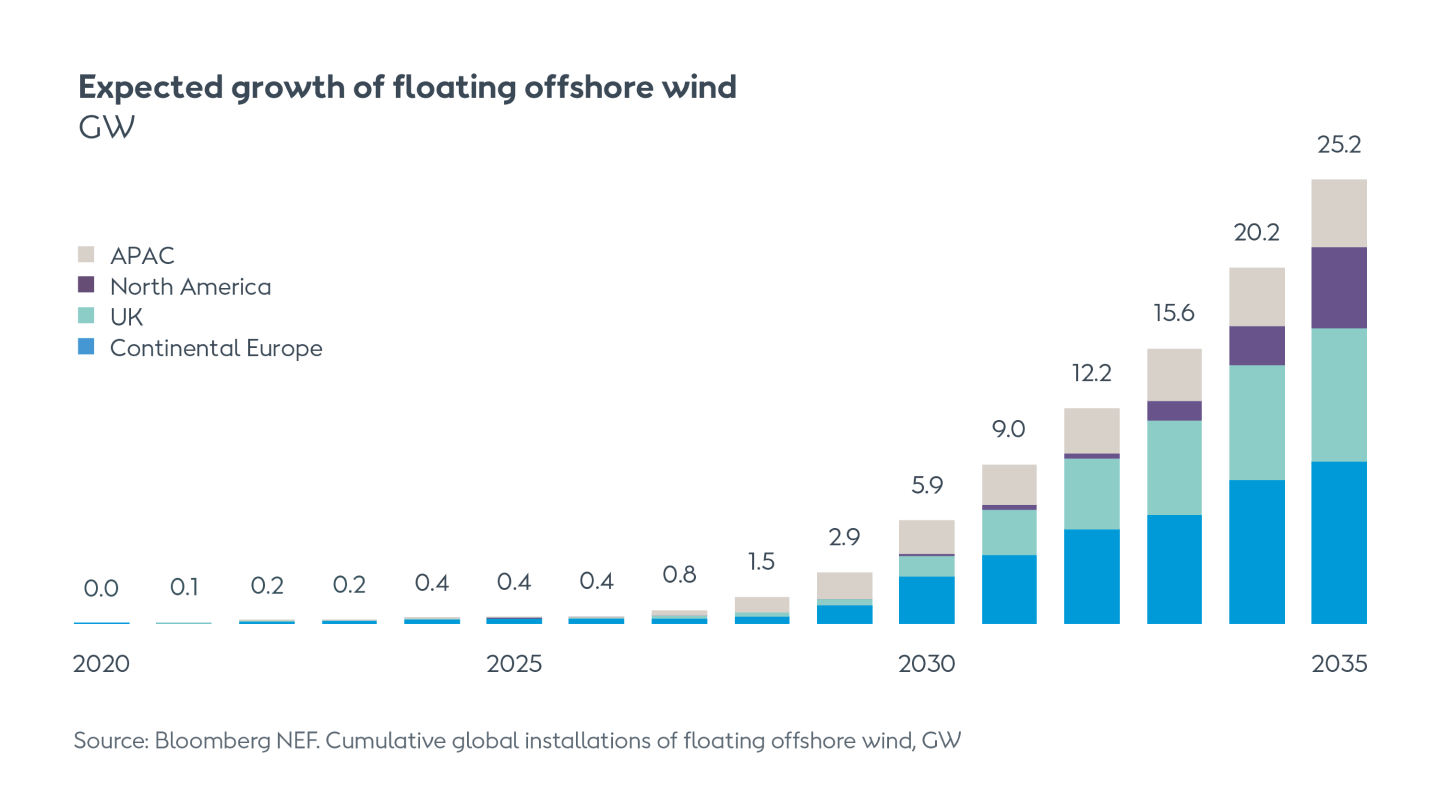

| Growth |

| Benefits |

| Our projects |

| FAQs |

Climate targets

Floating wind brings offshore power generation to deeper waters, which are abundant. Regions where seabed-fixed turbine foundations are impractical can now look into floating foundations – from the Pacific Ocean off the coast of California to Japan. And in deeper waters, wind speeds are often greater, meaning more power.

Jobs

A modern 1 GW seabed-fixed wind farm creates more than 18,400 direct and indirect jobs in development, construction, operation, and decommissioning. We expect floating wind to be similar.

Biodiversity

Each wind power solution has its benefits. Floating turbines can be installed less noisily, with smaller vessels, and further from bird migration routes. Seabed-fixed turbines can host biodiversity projects such as ReCoral.