Green fuels for Denmark

Getting there will require an ambitious ‘all-of-the-above’ mitigation policy, using all relevant means to decarbonise energy use. It cannot be achieved without large scale power-to-X technologies. We’re in a hurry to develop and deploy renewable hydrogen and e-fuels production at scale. And even if all this is implemented at once, it will take around a decade before renewable hydrogen can become cost- competitive to its fossil alternatives.

Still, we expect this to happen. We have seen costs of renewable power generation decline rapidly to the point where renewable generation from solar and on- and offshore wind is now cheaper than coal or gas-based power generation. This presents a unique opportunity to leverage renewable energy in decarbonising other sectors. And today, just as with renewable power years ago, we see both future producers and consumers of renewable hydrogen flocking to invest, to set the development in motion. Once the ball starts rolling, we might even be surprised by the speed of the development – as has been the case for wind, solar and battery technology.

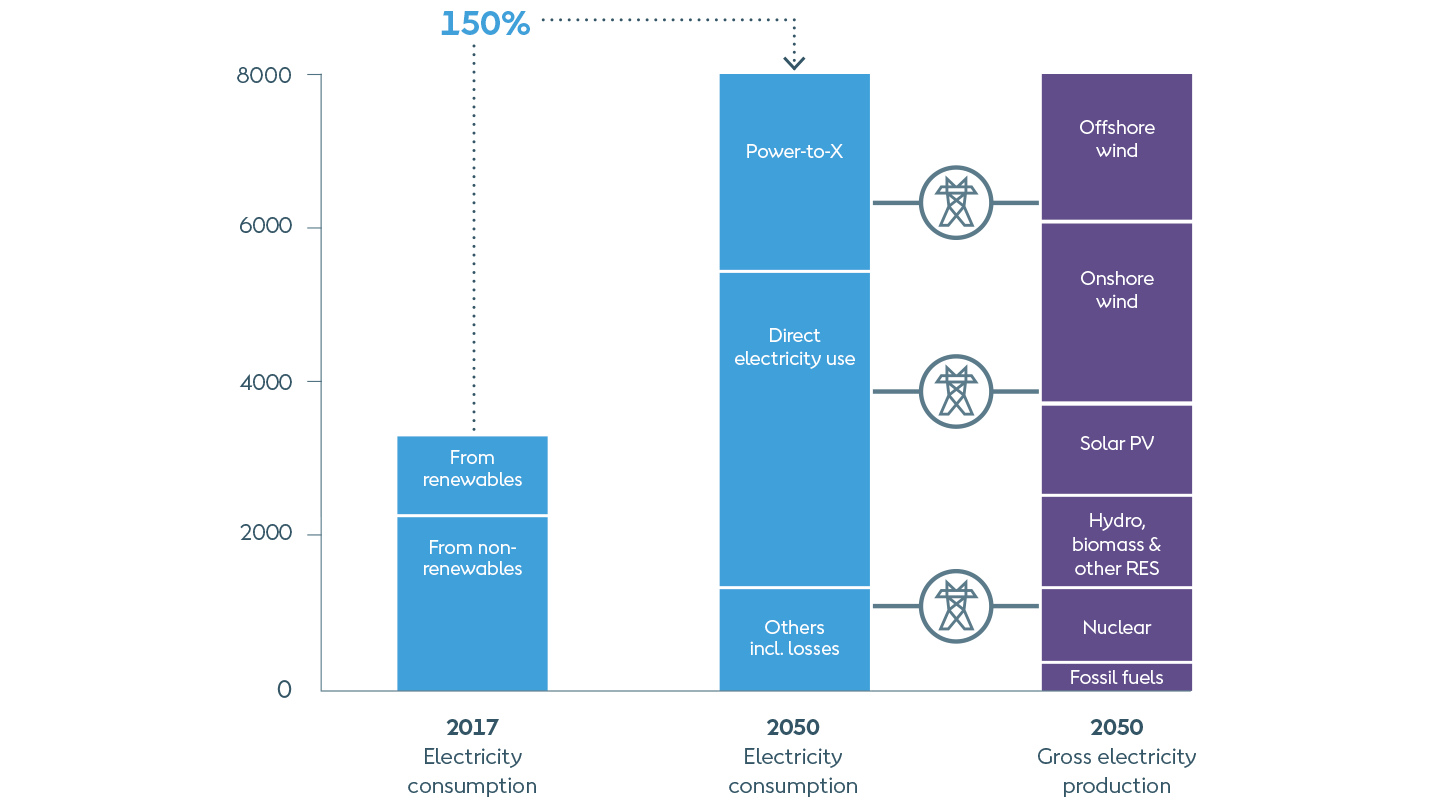

Much remains to be done. And the effort required is staggering. The EU Commission estimates, for example, that for Europe to reach its target of becoming climateneutral by 2050 will increase power demand by up to 150% compared to today. While some of this new demand will be driven by direct electrification and some of it by general economic development, production of renewable hydrogen and e-fuels will drive more than half of Europe’s growing power demand towards 2050. Citation European Commission 2018, A Clean Planet for all, COM(2018) 773, 1.5TECH Scenario

For power-to-X – and the green transformation at large – to succeed will require effort from policymakers, investors, producers of renewable energy and industrial consumers. At Ørsted, we’re committed to doing our part in scaling up renewable hydrogen and e-fuels. With this paper, we have outlined a way forward towards deep decarbonisation.

At Ørsted, we develop and construct renewable energy projects across the globe, with large-scale renewable electricity projects operating or underway in Northwestern Europe, the United States and the Asia-Pacific region. Building on these experiences, we have ambitious plans to accelerate deployment of renewable hydrogen production and power-to-X, with a current focus on North-western Europe, and an eye on other parts of the world.